Beijing Sino Steel Engineering & Equipment Co., Ltd. is

concentrating on developing of ferrous & non-ferrous making and

Rolling technology, mainly.

As one of the most experienced Chinese suppliers of complete line

and components for steel and non-ferrous industries, Beijing Sino

Steel Engineering & Equipment Co., Ltd. is engaged in design, manufacturing, engineering and service activities on word-wide basis.

Overseas Partners (Office):

India, Indonesia, Malaysia, Thailand, Korea, Turkey, UAE, Qatar,

Iran, Saudi Arabia, Kuwait, Germany, France, Canada, USA, Brazil,

Etc.

MAIN SCOPE SUPPLY:

EPS Project Line:

EAF, LF, Continuous Casting Machine, Preheating Furnace, Hot

Rolling Mill Line, Cold Rolling Line, Centrifugal Casting Line,

Slitting Line,Cut-to-length Line, Cleaning Line, Pickling Line,

Coating line, Levelling line, Billet grinding line ETC.

Components & Parts:

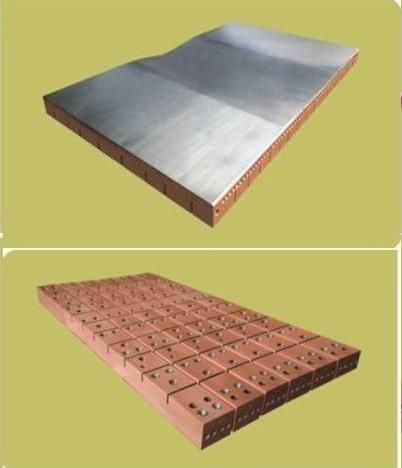

Mill stand, Coiler, Uncoiler, Gearbox, Leveller, Copper Mould Tube,

Copper Mould Plate, Water Jacket, Water Cooled Cable, Forged Rolls,

Casting Rolls, Roll Shell, Roll Core,Bearing, Universal Shaft,

Lathe, ETC.